Challenge

Our customer, a marine foundations and piling equipment company, had been contracted to supply a pre-piling template to ensure the accurate installation of piles for an offshore wind farm project.

Their customer had requested the inclusion of an air bubble curtain as a noise mitigation measure. This is an environmental consideration to dampen and absorb the sound of underwater construction to prevent hearing loss and noise harassment of marine mammals. In addition, we were asked to include control of the water jetting system which is used to enable suction release of the mud mats when the rig is being lifted and moved.

The real challenge was to get it right first time, as due to the subsea nature of the project, there was no opportunity for ongoing development or prototype testing. We collaborated with our customer to outline the concept, and also during the design and development of a bespoke solution. After investing a great deal of engineering time, we were able to simplify the overall design to reduce build complexity and potential for failure.

We also worked with the customer to provide validation of their air requirements and produced a full set of 3D models for their approval.

Solution

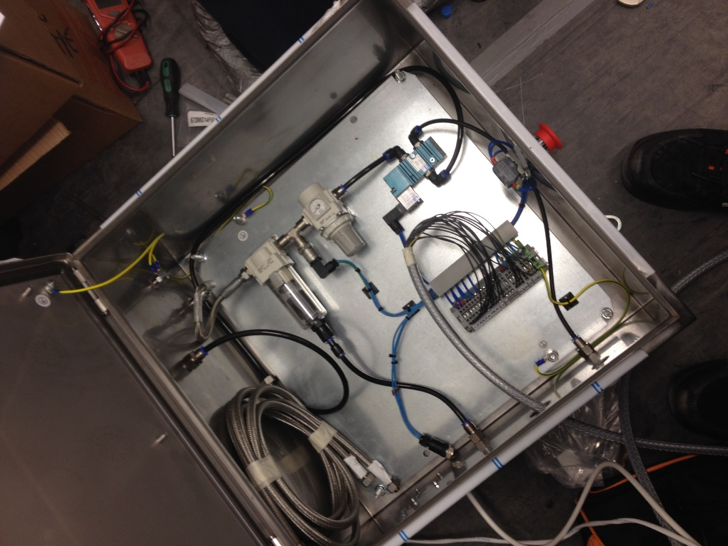

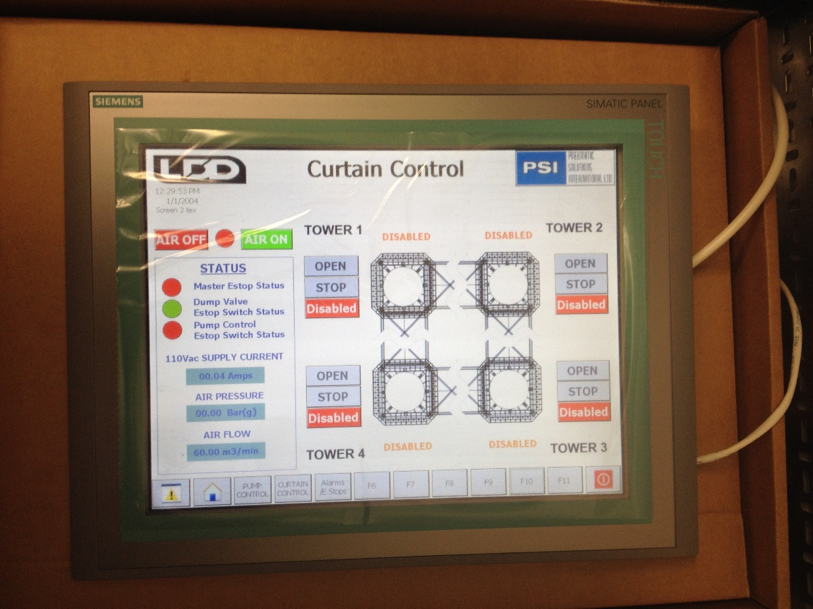

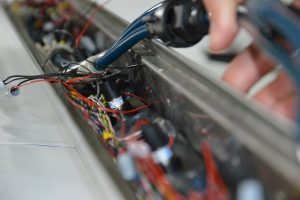

The solution delivered was a complex electro-pneumatic system consisting of a series of actuators and a control system mounted into subsea pressure vessels with a subsea distribution manifold for the air. There were also a number of control panels and a touchscreen interface for installation into the control cabin, where PSI were able to utilise their own internal control panel build proficiency.

In addition to PSI’s own engineering expertise, PSI brought together the skills and capability of a number of component manufacturers, to create a system that was fit for purpose in a very demanding underwater environment.

The project in pictures:

Subsea Actuator Pressure Vessels, Control System mounted into Pressure Vessels, Subsea Distribution Manifold

A Success Story

To design, build, test and supply a complete subsea control system was a tremendous up-taking, and a challenge we were keen to meet. By working very closely with our customer, we were able to provide ‘a right first time’ control system – essential due to the location of the project.

The installation and commissioning of the system and the coastline went smoothly. The equipment worked well with no issues, failures or water ingress into the subsea components throughout the duration of the wind farm construction project.

The success was such that it was generally considered to be a blue print for subsequent windfarm installation projects.