Challenge

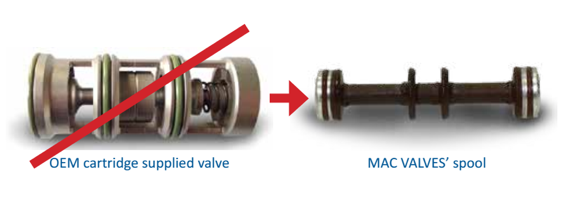

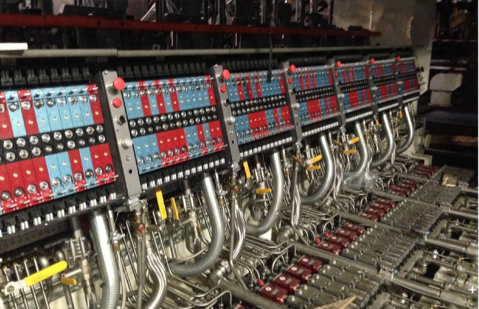

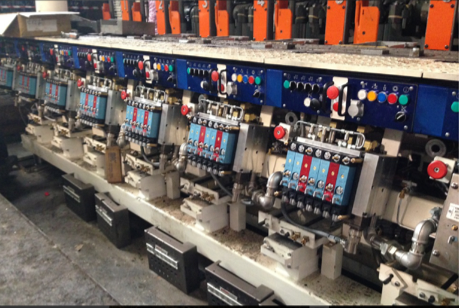

Our customer was using the OEM supplied cartridge style valves on their IS machines with 26 Line valve consoles. They had many issues with reliability of the Cartridge valves resulting in regular machine stops to replace valves. The OEM supplied valves had regular issues due contamination in the solenoid pilot valve exacerbated by the weakness of the return spring. The results of this contamination showed up as slowing of the response of the valve and necessitating repeated adjustment of the signal timing and ultimately section down time for valve replacement particularly in the challenging functions of invert/revert and Mould Open/close. The manual overrides on these valves was also incredibly easy to operate with a risk of inadvertent operation as they required only the slightest of touch to move.

Engagement

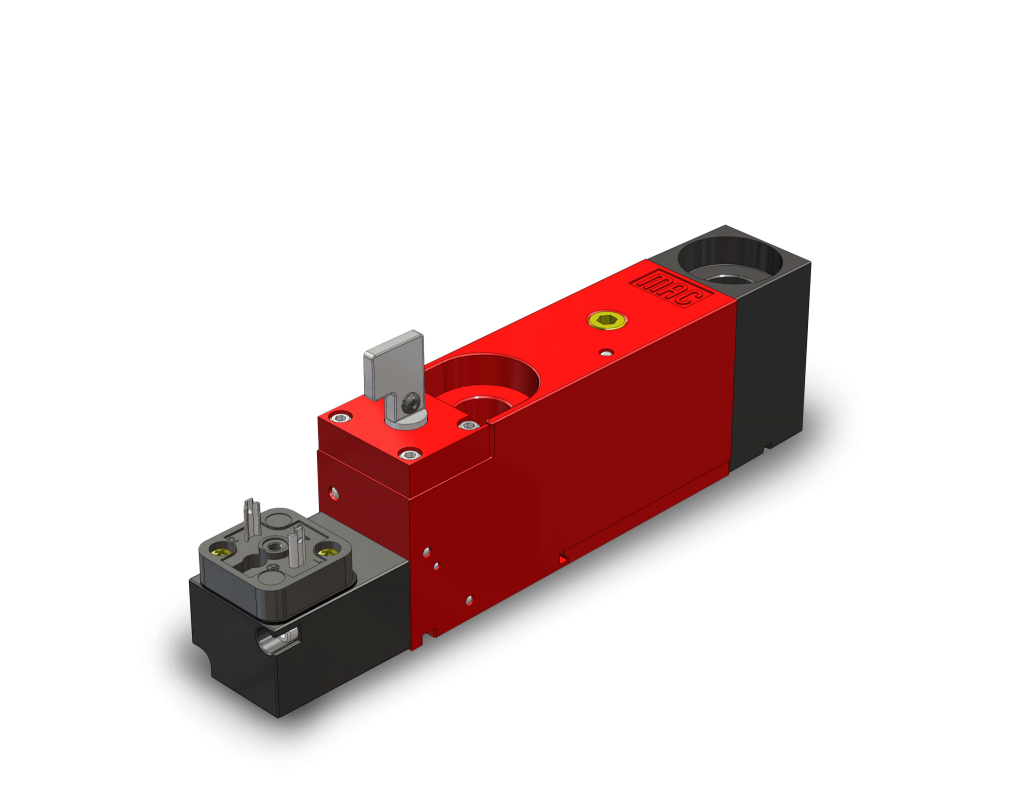

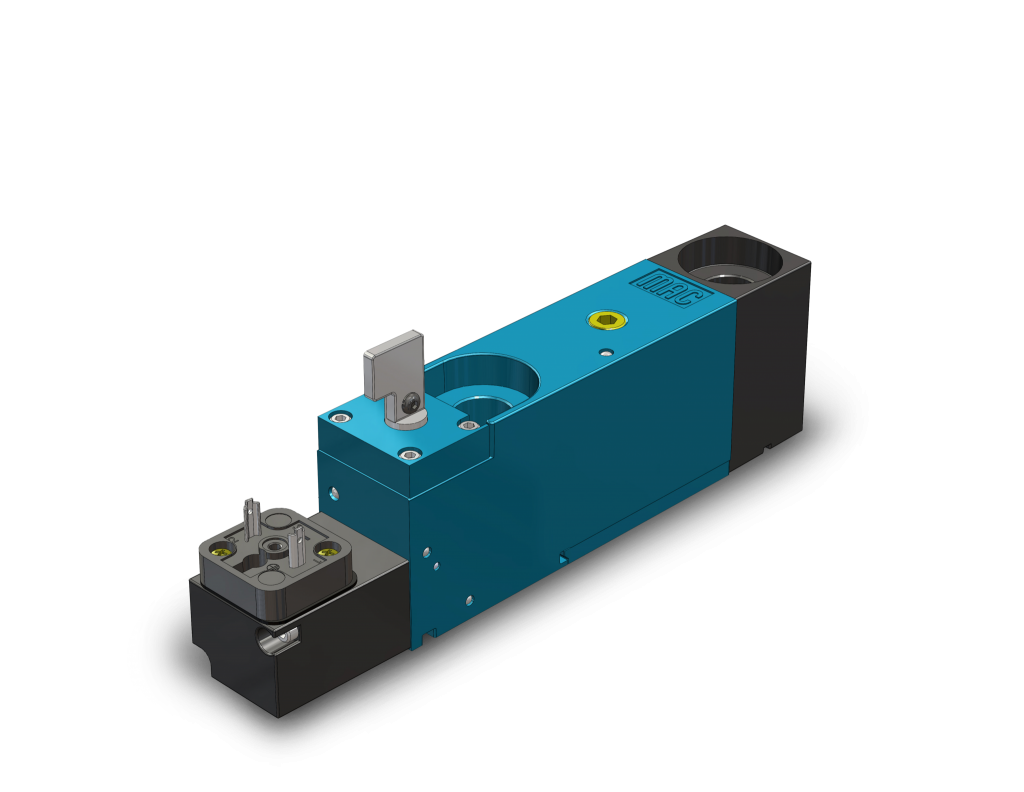

The OEM valve is well known in the industry to be the source of costly maintenance and Mac used their patented Technology to address these issues designing a superior valve as a 100% drop in solution. We carried out a full section trial on the machine at the customer to evaluate the Mac technology and the results were obvious in a very short time that the Mac section ran more efficiently with less stops. We identified another issue with the use of these valves that Mac could easily address – The OEM valves are all grey and the environment on the machines means that regularly it is not easy to identify if the valves are Normally open or closed. Although this does not affect performance they could add to the down time when the valve function had to be checked – Mac resolved this with Anodising the valves simply in different colours.

Solution

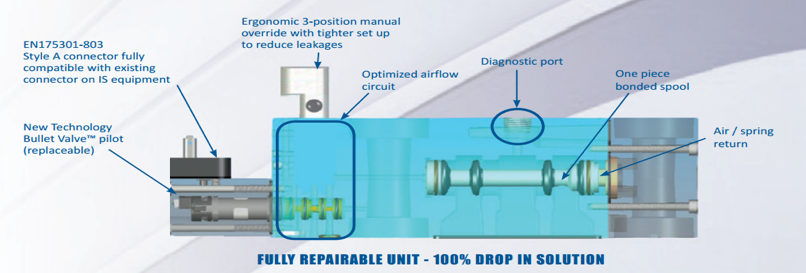

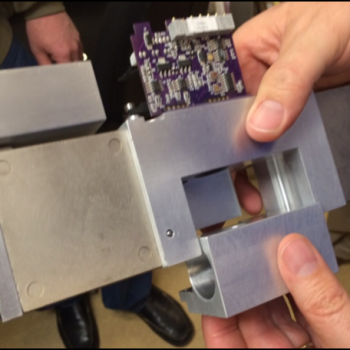

The Mac EMA valves are exactly the same Size, footprint, dimensions, electrical connector and LEDs as the OEM supplied units but inside is entirely different. The Mac Valves bonded spool technology replaces troublesome cartridges and the patented MAC high temperature Bullet Valve® pilot instead of the OEM pilot valve with a weak spring and susceptibility to contamination provides a significant increase in valve life – 100 million cycles (est.) MTBF life time.

The 3-position manual override is smooth with a positive feedback of position without being difficult to operate and this greatly reduces the potential to be operated inadvertently.

In true Mac style they additionally added a diagnostic port to the valves to speed up fault finding enhancing the potential to lower maintenance costs by reducing unnecessary valve changes. The valves can also be fully repaired with individual parts available for the spool, manual override and the solenoid pilot.

Colour coding of the valves ensure no confusion on the valve functions.

Benefits

From first installation customers can see that the Mac product is truly a 100% drop in solution product and the performance improvements can be quickly identified. Customers have noticed a significant drop in the replacements of the valves in comparison to the Cartridge valves.

Customers have been using the Mac EMA valve on existing machines have been so impressed they have also specified the Mac Valve to be factory fitted for delivery of new machines from the OEM.