Challenge

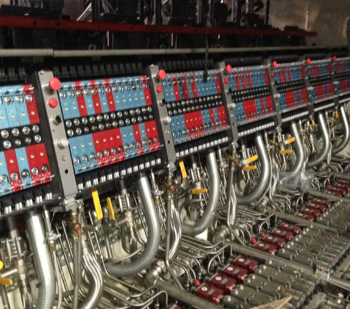

Many modern glass production machines use proportional pressure control valves to allow multiple changes in air pressures used during the 360o cycle of the machine. The applications for the proportional control include plunger up movement, plunger cooling, counter blow and other blowing functions.

Fast and precise control of the pressure changes as well and pressure consistency is required to maintain quality. The proportional pressure valve must also survive the rigours of working in the extremely harsh environment of glass production.

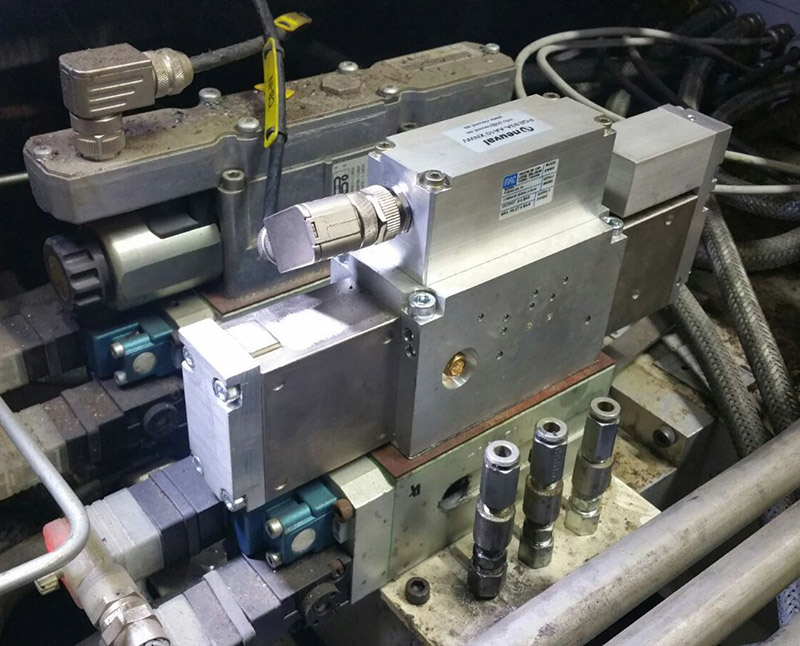

Our customer in this case, was suffering with short lifetime and high maintenance costs of the proprietary proportional pressure controllers on their machine. They were experiencing a lifetime regularly below 6 months. This was often as a result of contaminated air returning from the plunger, but also due to electrical faults which are required to be sent to the manufacture for repairs.

Engagement

Following a period of close collaboration between our customer, Mac and ourselves spanning a number of factory visits, we provided trial units which proved very successful. The new solution delivered an improved performance over the OEM equipment with a more stable pressure trace and a strong resistance to contamination.

The trial had proven the resolution of issues with the plunger cooling application but there was further opportunity to improve the plunger up reliability. Further investigation showed the root cause of the plunger up issues were as a result of the heavy oil contamination carried back to the unit in the returning air.

Looking for a solution, the main challenge was a lack of space available to mount an external valve. However, with some clever design, Mac were able to include an additional valve into the same dimensions. This meant no modifications were required to the machine itself, while also removing the potential for the contaminated air to affect the unit. The trial units were fitted and were an immediate success more than doubling the life of the original units.

Solution

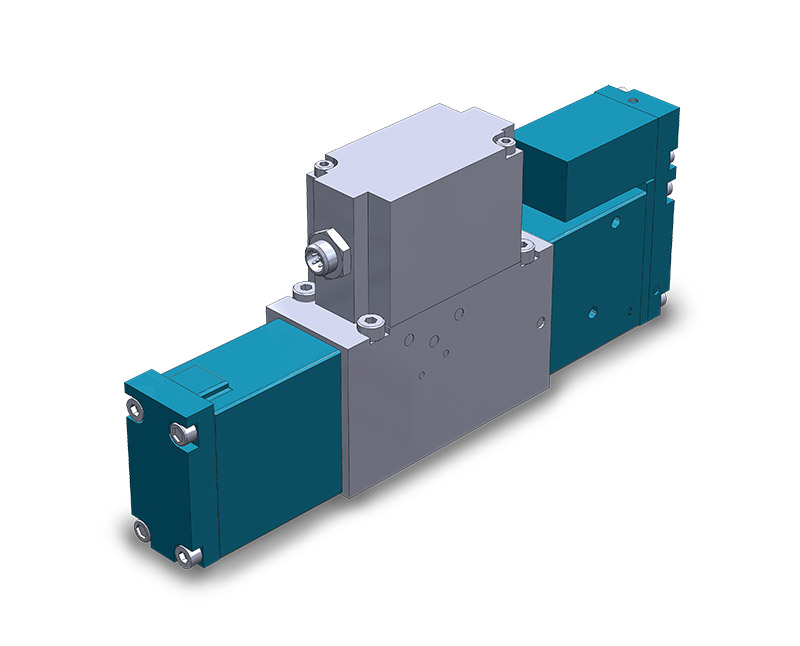

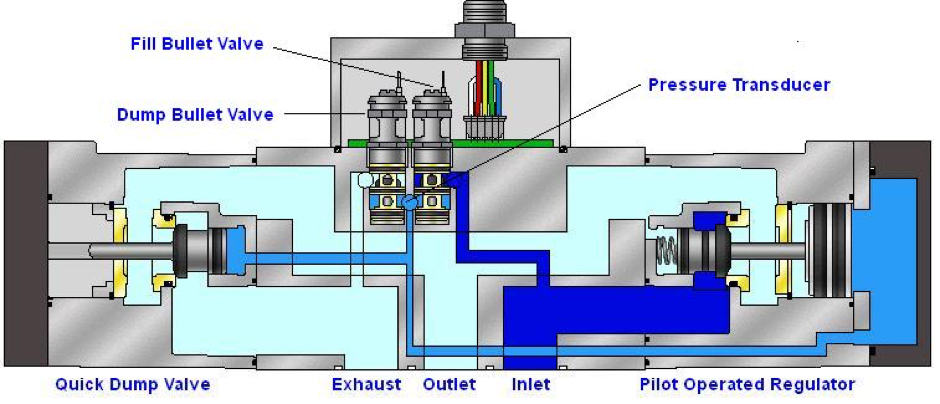

The solution delivered was the Mac Proportional Quick Exhaust Valve (PQE) designed specifically for glass IS machines.

The MAC PQE technology brings the following advantages:

- 100% drop in replacement for the OEM supplied solution for Narrow Neck Press and Blow (NNPB), Press and Blow (PB) and Blow and Blow (BB) applications with several interfaces available.

- Twin booster design for better accuracy and lower electrical consumption.

- Individual Mac bullet valve technology pilots, operating boosters for inlet and exhaust.

- Short and consistent response times for better control of each step of the process, with dual transducers providing extreme precision control based on actual pressure measurement of outlet pressures.

- High temperature seals for long life, improved resistance to high temperature and aggressive lubricants.

- Fewer parts to simplify maintenance.

- Repair inlet and exhaust kits available and fully field repairable.

The MAC PQE technology brings the following advantages:

- 100% drop in replacement for the OEM supplied solution for Narrow Neck Press and Blow (NNPB), Press and Blow (PB) and Blow and Blow (BB) applications with several interfaces available.

- Twin booster design for better accuracy and lower electrical consumption.

- Individual Mac bullet valve technology pilots, operating boosters for inlet and exhaust.

- Short and consistent response times for better control of each step of the process, with dual transducers providing extreme precision control based on actual pressure measurement of outlet pressures.

- High temperature seals for long life, improved resistance to high temperature and aggressive lubricants.

- Fewer parts to simplify maintenance.

- Repair inlet and exhaust kits available and fully field repairable.

Benefits

Our customers immediately saw a reduction in the failure rate and costly testing and maintenance time.

The Mac PQE units are fully field repairable and following some training provided by Mac, the customers are now able to refurbish the units themselves when the need arises.

Customer feedback showed the following benefits:

“More consistent plunger up process time”

“The duration of the holding pressure for the plunger is extremely consistent from cycle to cycle”

“Lower pressure can be used during all the plunger process, resulting in an improvement of

the bottle neck quality, and a wear reduction on mechanical parts”