MAC Valves have a reputation as an innovator in solenoid valve technology. These innovations and the patents that evidence them cover a vast number of benefits, such as speed, repeatability, ease of maintenance and application specific modifications. Underpinning them all is reliability. MAC valves incorporate extremely high solenoid shifting forces, a balanced design and an internal wiping action, to give you valves that don’t stick.

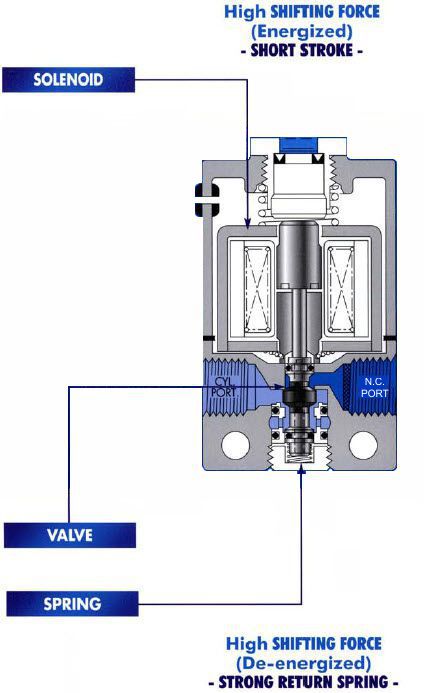

Typical Unbalanced Poppet 3-Way Air Valve

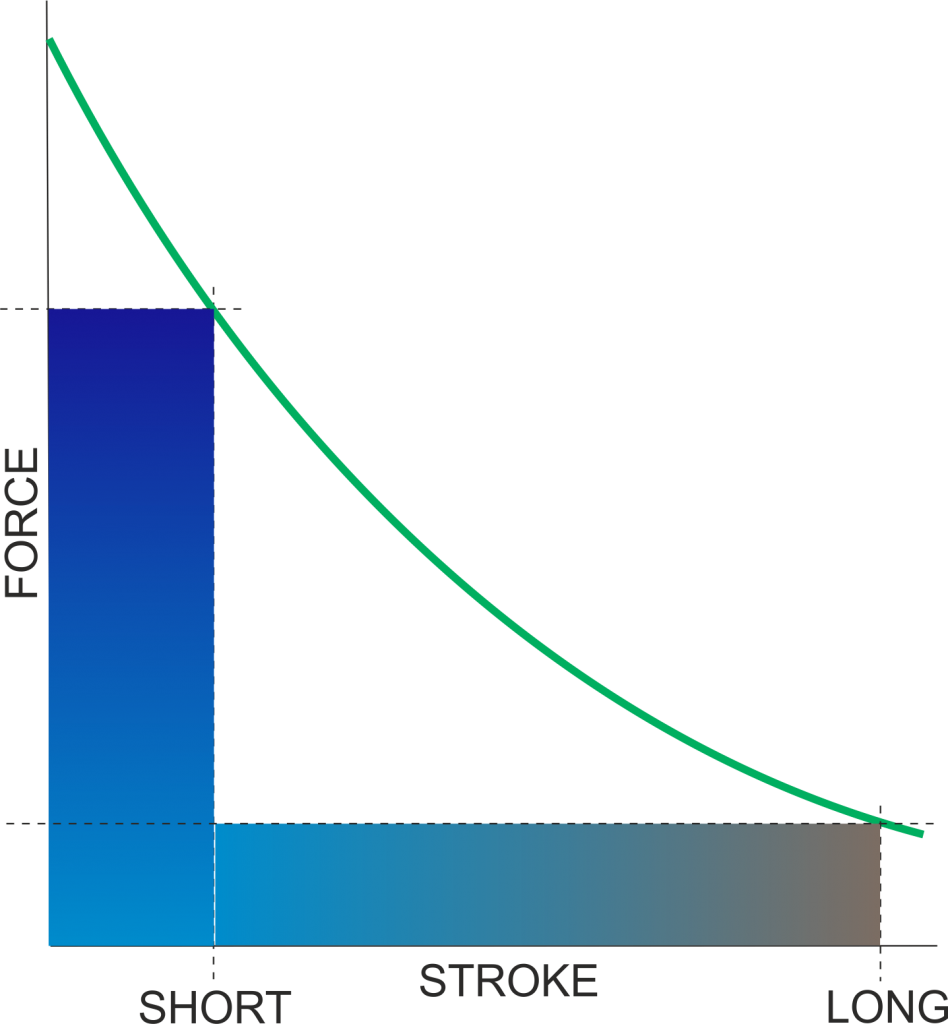

Typical valves incorporate an unbalanced design. For example, a standard Skinner or Asco design 3-way valve has an unbalanced poppet, which means that air pressure acts directly against the poppet seal. To maximise flow through a valve of this design, a long solenoid stroke is required which results in weak shifting forces. Though the spring force itself is constant, the air pressure against the sealing area creates a force that opposes the return spring shifting force, which reduces the force required to shift the valve. Force that is created by inlet air pressure varies, and the changing pressures affect energising and de-energising response times.

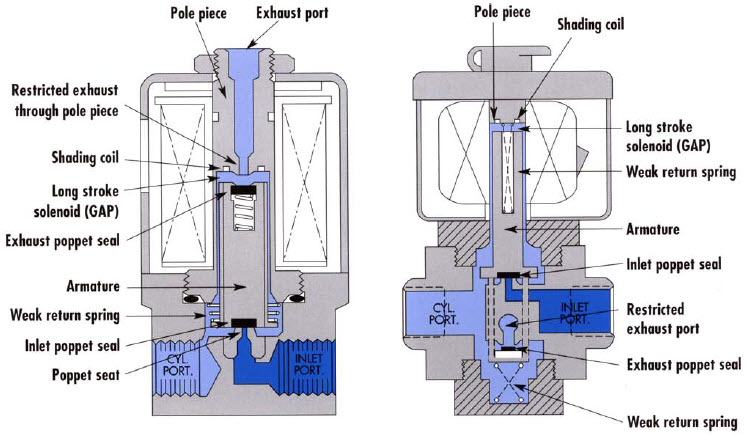

Balanced Poppet 3-Way Air Valve

The MAC Valve design incorporates a balanced poppet design and an annular orifice, resulting in immunity to varying pressure and a short stroke that produces high energisation shifting force. The high force return spring maximises both the energisation and de-energisation shifting forces during use. MAC valves also come with built-in wear compensation, because the valve stroke is shorter than the solenoid stroke which produces the shifting force. The solenoid closes regardless of the valve’s position, which virtually eliminates coil burnout. Thanks to the high forces that are achieved with the valve’s short stroke, the design delivers valves that dont stick.

All MAC valves are perfectly balanced and designed to work with the high forces that they produce to give you excellent results every time. The balanced poppets allow for direct solenoid operation for relatively high flow, and give minimised friction, and fast response times, no matter which MAC valve you use. The non-sticking MAC valves are the solution to for high speed, high reliability and arduous environment applications.

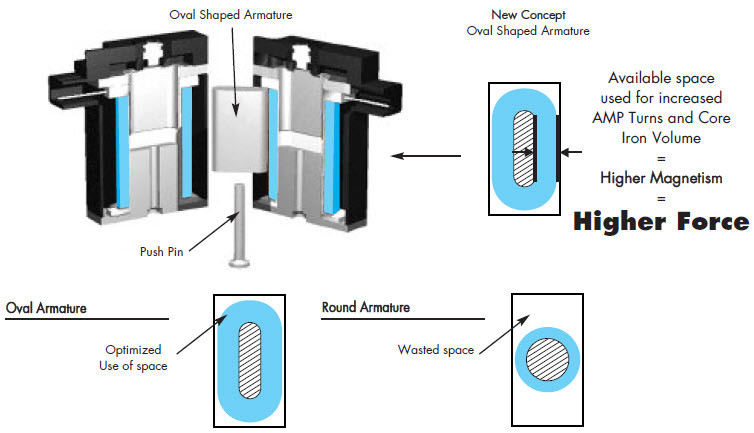

Oval Shaped Armature Solenoid – Maximised Shifting Forces

Compared with typical round armature solenoids, the oval shaped armature design found in many MAC valves results in much higher shifting forces due to the following:

- Increased coil windings (amp turns)

- Increased core iron volume

With more amp turns and core iron than conventional round armature designs, more shifting force is available to shift through contaminated air resulting in reliable shifting valves.

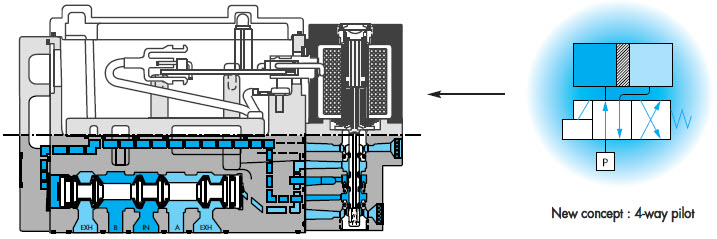

MAC’s 4-Way Pilot System – Maximised Shifting Forces

The balanced 4-way pilot valve provides maximum shifting forces in both directions by supplying air alternately to each end section of the spool, similar to a double acting rodless cylinder. This systems provides maximised shifting forces, equal forces at energisation and de-energisation, with no resistance to shifting at either end. The result is increased shifting reliability and faster, more consistent response times.

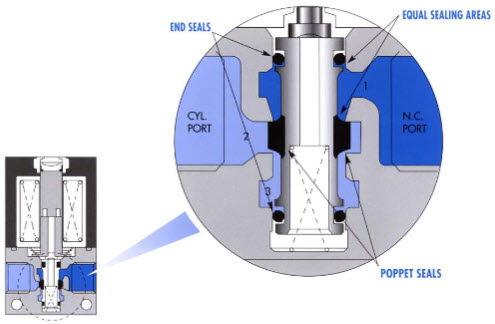

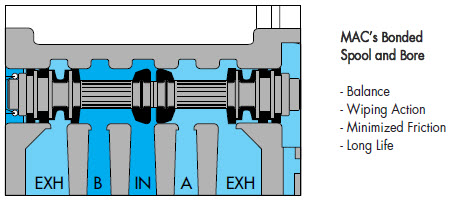

MAC’s Patented Bonded Spool and Bore – Balanced, Wiping Action, Minimised Friction

MAC invented the bonded spool and bore combination ensuring balanced operation and built in wiping action to contend with air line contaminants with minimal friction. Precision ground and chemically hardened bonded seals control compression and eliminate creep leading to optimum sealing with minimum resistance to shifting. Built in lubricants in the rubber compound enhance non-lube service and extends seal life.

A precision machined bore, roller burnished and polished, results in hard smooth surfaces with a glass-like finish to help minimise friction and wear. The end result is exceptionally long seal life.

MAC’s short stroking, lightweight aluminium spools produce fast, repeatable response times.