End Effectors for Collaborative Robots – PHD Pneu-Connect

There is a massive industrial transformation underway as we move towards the realisation of Industry 4.0. With it comes a raft of new technology, but one of the most striking and obvious to those working in their vicinity is the rise of collaborative robots (cobots).

One of the most widely recognised is the Universal Robots URx range, although there are many more options now on the market. These cobots primarily collaborate with human operators to assist in the fulfilment of repetitive tasks where it’s not possible, or preferred, to fully automate.

Part of the success of these robots is the simplicity of programming; where traditional industrial robots require detailed programming knowledge, cobots use graphical user interfaces, ‘teach modes’ and smartphone apps.

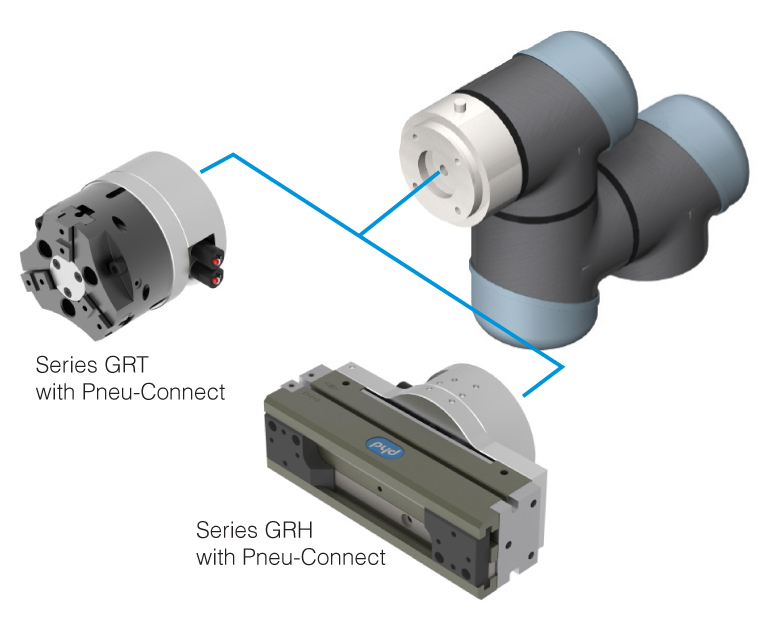

The collaborative robot itself is not the whole solution though. To do work, you also need an appropriate end effector. There are many options of end effector, and the type will often be determined by the application, but it’s important to make sure that whichever solution is selected can be integrated as easily as the cobot itself can be programmed.

To this end, PHD Inc have developed Pneu-Connect. A cost-effective pneumatic end-effector system providing seamless integration for collaborative robots. Designed around the leading Universal Robot (UR), the combined skills of PHD and PSI mean the Pneu-Connect can be adapted for many other types of cobot too. It’s quick and easy to make an initial ENQUIRY; follow the link and provide us with a bit of background and one of our expert application engineers will make contact to discuss.

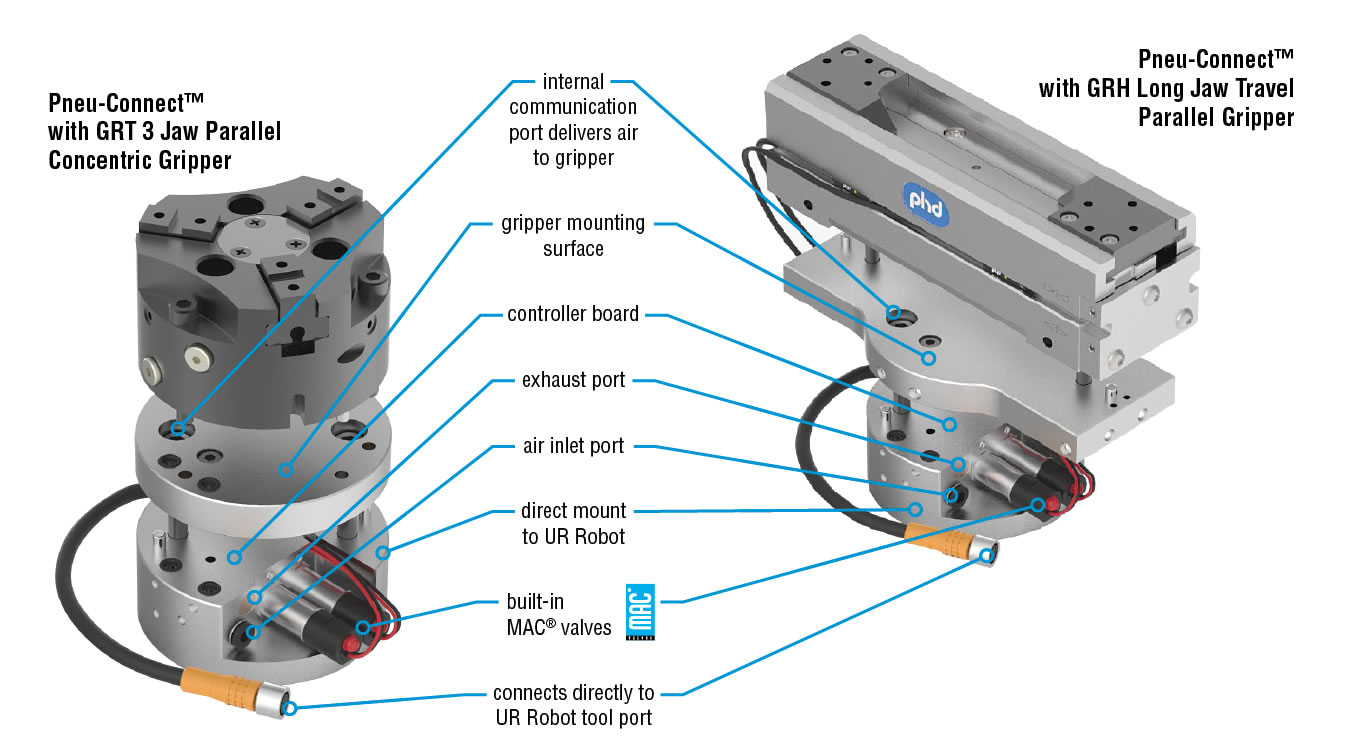

With a Universal Robot (UR) cobot, Pneu-Connect connects directly to the tool port on the robot arm making it easy to attach a PHD pneumatic gripper. The Pneu-Connect incorporates a built-in pneumatic directional control valve for opening and closing the gripper. A connector is provided on the Pneu-Connect that plugs directly into the UR robot tool port. The Pneu-Connect comes with a “CAP” which is an application specific to the UR collaborative robot. The “CAP” runs inside of the UR control software and provides a graphical interface making the pneumatic gripper easy to use and integrate with the cobot.

The power density of pneumatics allows for a superior performance to weight ratio when compared to some electric alternatives. This inherent property allows for lighter, non-payload robbing end-effectors, ideal for robotic applications. Additionally, when properly controlled, the compressibility of air provides intrinsically safe, back-drivable actuation capability.

Benefits include:

- Seamless, cost-effective, end-effector integration

- Ease of use

- Incorporated MAC® valves and control board

- Common jaw mounting for application specific tooling

- Couples directly to the robot arm tool port enabling pneumatic gripping capability

Be sure to weigh all the factors involved when selecting an end effector for a collaborative robot. Part weight, speed, required accuracy, and variance in part size and shape are all factors to consider. When the part size and shape have only small variances and there is a need for placement accuracy, a pneumatic gripper may be the most economical choice, making the Pneu-Connect package a cost-effective solution for your collaborative robot application.

For a product sheet on the Multi Part Handling Actuator

Or if you have more questions, please Enquire on our Talk to an Engineer page