Metal Recycling – a trial that’s proving its worth from day 1

This metal recycling company is trialling PSI’s Industrial Internet of Things remote monitoring solution with a planned 150 sensors, of mixed functionality – from temperature, to vibration, to current and more. An initial batch have now been installed and because the environment is ideal for an IIoT solution, results and potential can be seen immediately. The 150 sensors will transmit data to 2 gateways, and a LoRaWAN secure network used to send data to the Cloud, which the customer can see and interrogate on a centralised visual dashboard. The capability within the dashboard is extensive, with a layout map enabling the zooming in on the exact sensor in trouble. The same dashboard can be seen on a tablet, which can then be used as a guide to follow and locate the sensor in question, which in a factory of this magnitude, is of considerable benefit.

This is remote condition monitoring in its element as the industrial space is huge with few interior walls. The vast space and volume of assets that need monitoring means that the sheer scalability of an IoT solution offers so much more affordable flexibility than relying on a wired SCADA system alone. Industrial IoT offers data analysis capability, over and above monitoring and controlling and is, in effect, a digital twin of the asset being monitored.

PSI undertake the whole deployment, from detailed mapping of the factory to the placing and deployment of each sensor and gateway. All the customer need do is look at the data and take action when required.

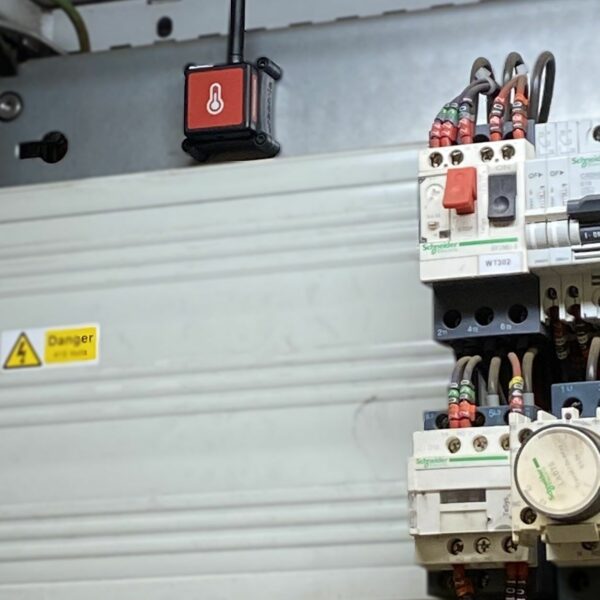

Here is the story so far in pictures. An Industrial sensor is highly robust, and built to sustain dust and dirt while being easy to install in difficult to access places.