PSI’s Industrial Internet of Things solution is practical and robust, using the core technology developed by PSI partner Urban.io, known for its niche of connecting disparate, remote or legacy/dumb assets, and developing solutions for some of the more challenging or harsh environments here in the UK. PSI are both a technology company and an industrial engineering company, which means that the PSI team already understand industrial environments, so the installation and project management will always be as robust and reliable as the technology solution itself. PSI source other IoT technologies as the challenge requires.

Remote Condition Monitoring: Recycling

Who: Metal recycling group with locations across the UK and the globe.

Challenge: To wirelessly connect potentially hundreds of legacy and hard to reach assets, within a huge factory space and harsh environment.

Solution: In fact, the PSI/Urban.io solution is a perfect fit for this type of environment. The hardware is built for harsh environments and the huge open interior (with few walls) lends itself to wireless connectivity and speed of installation.

The test system (of 150 sensors) is now underway with a first batch installed and monitoring. Learn more >>

Utility Consumption

Who: Food delivery company.

Challenge: A dark kitchen environment within buildings comprising many pods requiring submetering, or the breakdown of energy usage by franchisee.

Solution: PSI’s sub metering assembly work expertise ensured a bespoke and practical solution to the data insight need. The end result was layered data insights from asset types across organisation, asset types across locations, asset types in location and asset type detail.

Flood Sensors

Who: Anglian Water

Challenge: To vastly reduce maintenance time and minimise the costs and disruption of flooding in sewerage systems.

Solution: Self sustained gateways (5km radius, each reporting on 2000 sensors) running on solar panels and communicating using LoRa signal to the sensors installed within the sewerage system. Data insights enabling rapid response to and exact location of sewers in trouble.

Remote Condition Monitoring: Rail

Who: South West Rail

Challenge: To read sand hopper level and position of the vehicle on track to 40mm; challenges that went beyond a standard sensor and data transmission.

Solution: A whole remote monitoring solution was developed using revolutionary point cloud technology to read the sand level within the train’s sandbox or hopper. A control box, called a T-box, was also designed and built in-house, to power the point cloud technology ‘head’.

To learn more on this case study and others in the rail industry, head over to PSI’s sister company for Digital Rail – Transportise.

Web Enabled Solenoid Valve

Who: Utilities Sector

Challenge: To enable remote and independent solenoid valve control for any compressed air or inert gas, in addition to that already in existence – liquid.

Solution: a new IoT remote controller that can operate a single solenoid valve over 250,000times. Latching technology enables industrial and commercial use on air and inert gas systems.

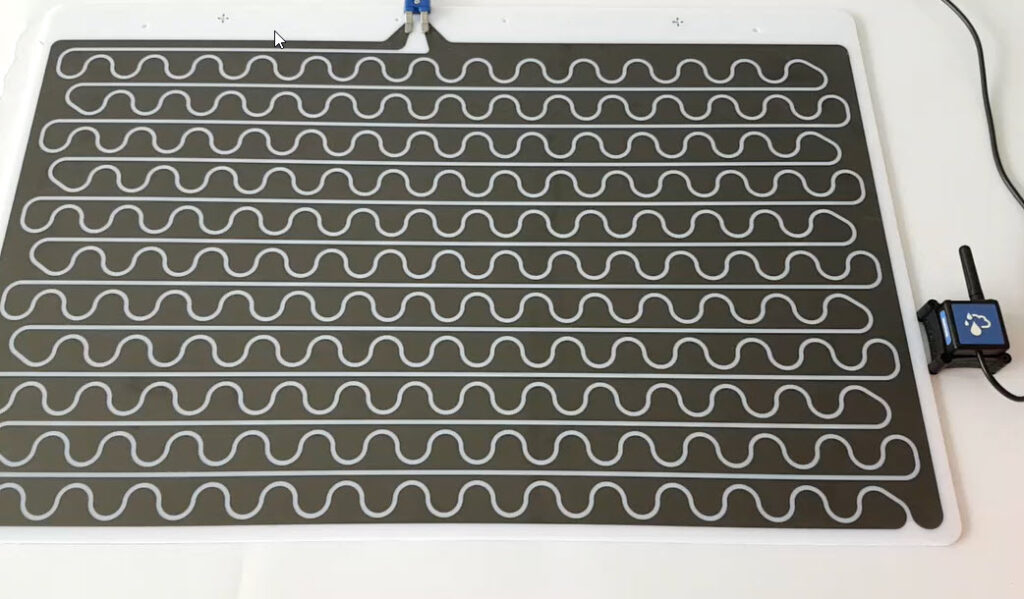

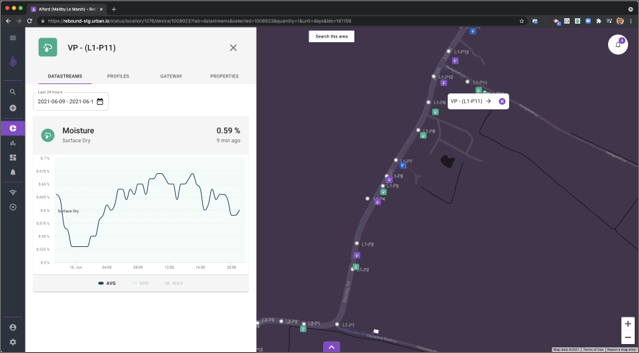

Preventing Shaft Floods

Who: Defence organisation

Challenge: To monitor difficult to access legacy shafts in a barracks environment (which house cables, ductwork, conduits and prone to leaking pipes), outputting the data to a cloud based insights dashboard. Security of data was of the utmost importance.

Solution: Utilise moisture mat technology in conjunction with humidity sensors. The moisture mat was set at the bottom of the shaft, with humidity sensors placed near the bottom. Both show near real time data to provide an early warning system of a leaking pipe. The data is relayed to a gateway via an encrypted local network and to the cloud provider via encrypted mobile communication network.