Hygienic Design for Food and Beverage Applications

The development of food manufacturing machinery has at its forefront the requirements of hygienic design.

The food industry places extreme demands on plant and machinery, from the processing itself through to primary, secondary and final packaging. There are a number of challenges faced when designing plant and machinery for use in these applications and they are as complex as they are far reaching.

Many design challenges are similar to those of plant and machinery used in other manufacturing environments. For example, downtime reduction, energy efficiency, total cost of ownership, standards compliance, operational safety and commissioning simplicity. Forward-looking technologies are essential in order to meet the growing demands for flexibility and modularity. The use of IO-Link-compatible sensors and actuators can be a big step in the right direction.

Processing Area

Primary Packaging

Secondary Packaging

Tertiary Packaging

Hygienic Design

Standard Components

However, there are two critical additional challenges faced when the application is in a processing or primary packaging area. These are; the need to reduce the time taken to clean machinery, and the inherent need to deliver a hygienic design overall.

Hygienic Design

The principles considered by hygienic design include the avoidance of structural weak points that can lead to hygiene related hazards. To support this, the cleaning capability of the materials, surfaces and structural elements are key. Dirt of any kind must not adhere or accumulate, or it must be easy to remove. All materials used must be resistant to cleaning agents and have the appropriate conformity for use in the food industry.

Hygienic Design comprises of:

- Legal specifications and standards for the design of components and machines up to entire production areas and factories.

- Legal specifications and standards for selecting materials.

- Recommendations by relevant institutions which greatly exceed statutory requirements.

- Approval/durability of materials for the corresponding cleaning processes and cleaning agents.

- Installation approaches and products for optimum design of the corresponding zones.

These increasing demands on the hygienic design of the production environment increase the cost of components. Modern installation concepts with decentralized IO modules or passive distributors can counteract this development.

General Design Guidelines

Field bus modules, passive distribution boxes and other control enclosures should be fully welded making the entry of dirt impossible.

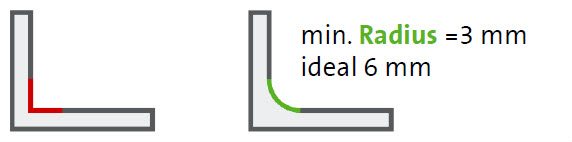

It is best to avoid 90 degree corners, instead using an appropriate radius to enable perfect cleaning.

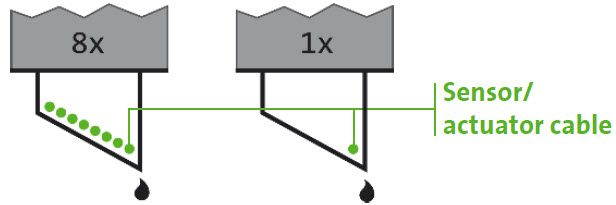

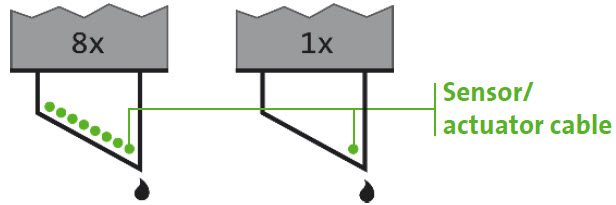

Using passive distribution boxes avoids complex parallel wiring of sensors. Instead of parallel wiring, a home run cable made from compliant materials can be used to simplify and reduce the amount of cables required.

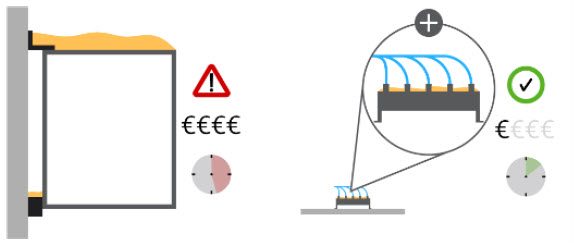

Hygienic installation of terminal boxes is time consuming and expensive. By decentralising the connectivity using stainless steel field bus modules, the ‘dirty area’ is reduced significantly.

Installation Concepts

Correct Installation

Hygienic Design does not stop at components and devices. For good cleanability in the processing area, the electrical installation must also be correctly run.

- Parallel installation of cables on stainless steel grids

- Leave gaps so that the spaces between the cables can be cleaned with pressure washers

- Fasten the cables with cable ties, usually made of detectable plastics

| Use the advantages of decentralised installation to save time and cost! |

For the Food Industry

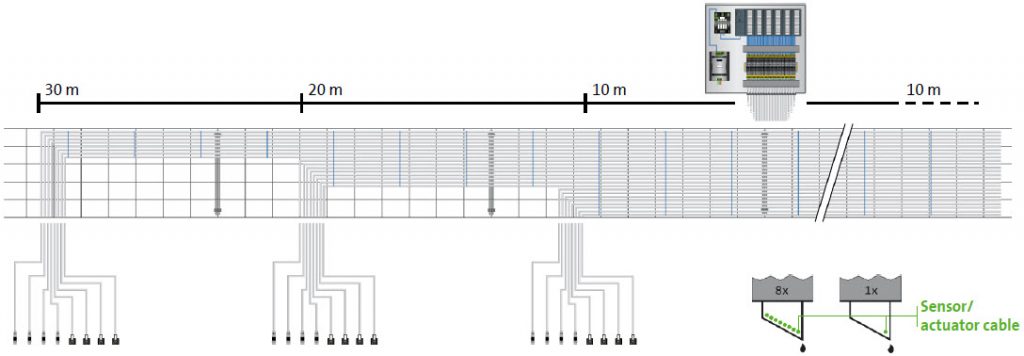

Installation concept: POINT TO POINT

| Number of sensors/actuators | 48 |

| Wires installed in mesh (m) | 960m |

| Number of cable ties (every 30cm) | 2880 |

| Mesh length | 60m |

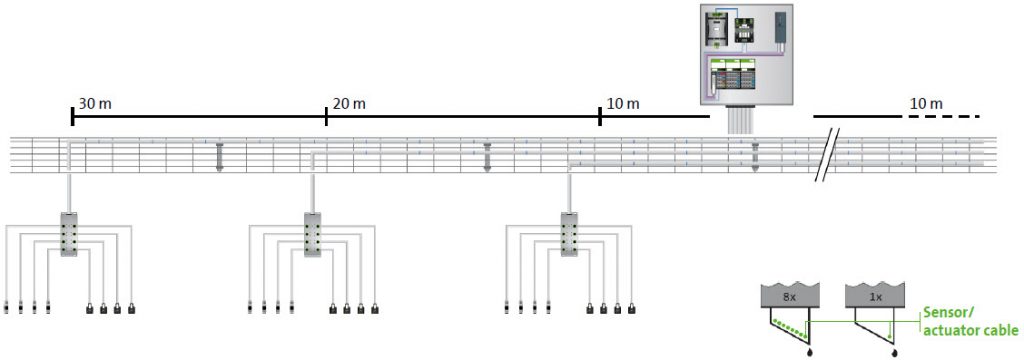

Installation concept: PASSIVE

| Number of sensors/actuators | 48 |

| Wires installed in mesh (m) | 120m |

| Number of cable ties (every 30cm) | 360 |

| Mesh length | 60m |

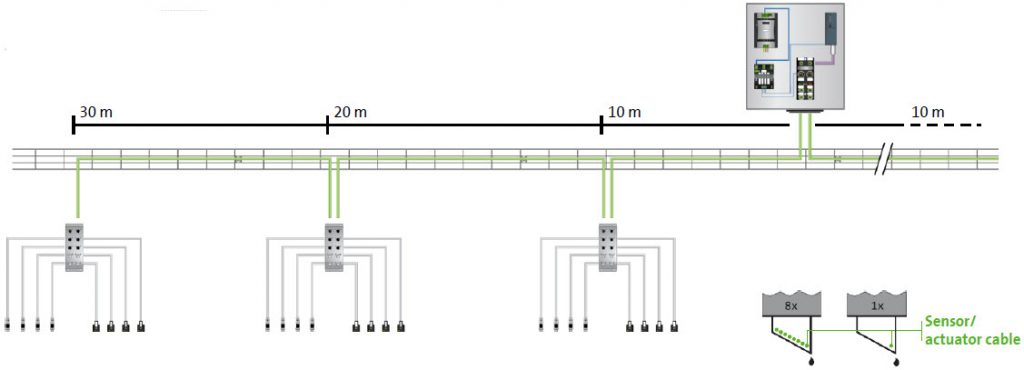

Installation concept: MODULAR

| Number of sensors/actuators | 48 |

| Wires installed in mesh (m) | 60m |

| Number of cable ties (every 30cm) | 180 |

| Mesh length | 60m |

Looking at the installation concepts above, it’s clear to see how using modern installation concepts enables a more hygienic design and simpler cleaning. However, it offers much more than that. With reduced wiring volume and complexity it also addresses some of the standard requirements for machine design. For instance:

- The intelligence built in enables a reduction in downtime through simpler fault finding.

- Total cost of ownership is reduced through reduced labour during installation and simpler maintenance and repair.

- The use of forward looking technologies and easy commissioning.

PSI Technologies and our partner Murrelektronik, are able to provide a number of solutions for the food industry. With products that meet the legal frameworks, suitable for use in Zones 1 – 3, using materials appropriate for the environment, we can help you deliver better connectivity solutions for your food machinery.

For more information on Murrelektronik, click here…