The problem

A customer in the beverage industry was using standard OEM supplied ISO valves on their filling machines and found that regular cleaning washdowns with caustic solution was causing the corroded valves.

The solution

PSI Technologies provided a direct drop-in replacement MAC ISO valve and base with a corrosion resistant nickel-plating modification. This would provide the longevity needed while still maintaining a strict cleaning regime.

The nickel plating modification solved a specific, yet common problem. There was also an increased air flow from 1200 Nl/min (original valve) to 1600 Nl/min (new MAC valve). The significance of this lies in the potential increase in cylinder speed, which could improve production. The benefits of a MAC valve that really make it unparalleled stem from the well-earned phrase ‘valves that don’t stick‘. To the production manager, ‘valves that don’t stick’ simply means faster, uninterrupted production processes due to minimised downtime. This is a direct result of higher shifting forces, lower internal friction, faster response times and larger flows in a given size.

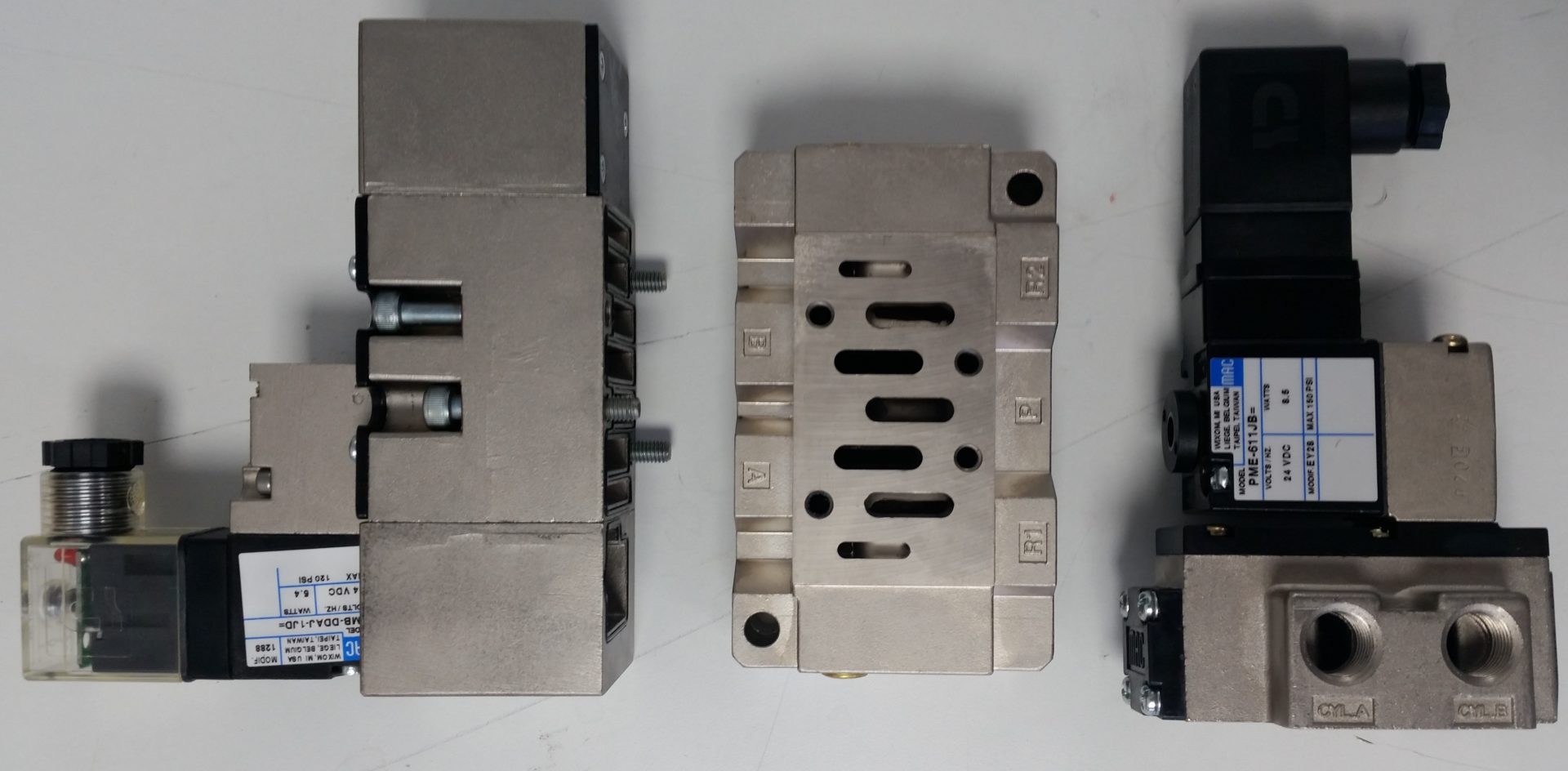

The image below show the ISO valve and base (left and centre) while the 3rd unit (right) is a MAC 900 series Nickel Plated replacing a standard Mac 900 series.