PSI Technologies are known as integrators of complex engineering projects, which means the deployment of a combination of skills from electronic design to control systems to programming. These case notes on PSI’s build of a train nose coupling system describe an intricate, extensive and fast-moving project with Tidyco, a hydraulic and pneumatics supplier to the rail industry.

Tidyco sought to utilise both PSI’s expertise in the rail industry and the skill set of the engineering team. The end customer was a leading global rail company and the project was to ensure a safe and compliant coupling mechanism within the nose cone.

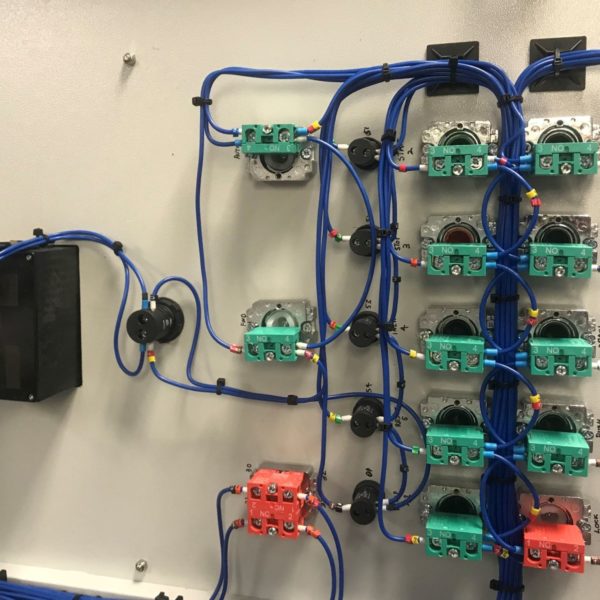

Experienced engineers at PSI designed the HMI, the user interface that connects the operator to the machine, in this case, the nose cone coupling system. The interface consists of hardware and software that allows the operator’s inputs to be translated as signals to the device or machine to take the desired action. In this instance, the sequencing of the class 395 coupling process; in other words, the safe joining of two carriages and the subsequent release as and when required.

Sounds simple but the speed with which this process happens, and the reverse engineering required needed expert control systems and electronic design knowledge coupled with programming skills and knowledge of VBA macros. Not only that, a test box and test panel had to be designed and built; an involved and critical project for safety and compliance reasons.

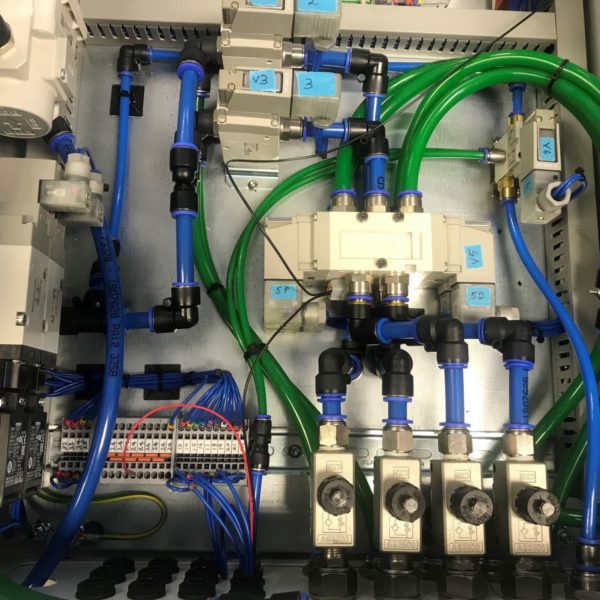

A problem to overcome was the reverse sequence, largely due to the housing of big cylinders combined with an inching, rather than continuous flow process. Reset was also a difficult hurdle to overcome as the air would be dumped back into the system. A category 3 safety dump valve was fitted along with two extra valves for safe start up and ultimate safety of the system.

Finally, a comprehensive user manual detailing the train nose coupling process was written. The whole project was completed safely in a record number of months.

The PSI engineering team are experts in the fulfilment of complex engineering solutions, with safety and compliance being paramount. From EN50155 to specialist EMC RIA 12 or LUL fire certification, multiple stakeholder projects like this one are where PSI excel.