No more physical manpower required with a heavy duty gripper

It may not look much to see the video but the weighty wedges were previously manhandled and released by two, needless to say, pretty strong men. The application is quite unique and the solution was specifically built for the job, utilising PHD’s ‘heavy duty’ GRK gripper and bespoke tooling.

The whole process takes seconds, but the special spring-loaded tooling for each wedge means that the wedges can be picked up without opening the gripper jaws, with the normal jaw opening for the vertical drop. This replaces what was previously a manual release system, and a lot of grunt.

The GRK heavy duty gripper is intended to be a workhorse in challenging industrial conditions. It makes a working environment safer, more often than not replacing tough manual labour.

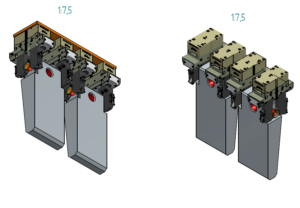

The GRK Parallel Pneumatic Heavy Duty Gripper has been extended to include four larger sizes. The GRK delivers the highest grip forces in its class and provides superior moment capacities and precision in a low profile package. a new feature is the wear compensating jaw guidance system enabling precision jaw movement throughout the life of the unit.

If you’re interested in keeping in touch, you can subscribe to our industrial automation newsletter which is 3 or 4 times a year